News

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Blog Articles

Unlocking the potential of metal powder for 3D printing heat exchangers

Unlocking the potential of metal powder for 3D printing heat exchangers

How additive manufactured cold plates improve thermal performance for Advanced Air Mobility

How additive manufactured cold plates improve thermal performance for Advanced Air Mobility

.png?updated=1692067033) How additive manufacturing can improve thermal performance of vapor chambers

How additive manufacturing can improve thermal performance of vapor chambers

Case Studies

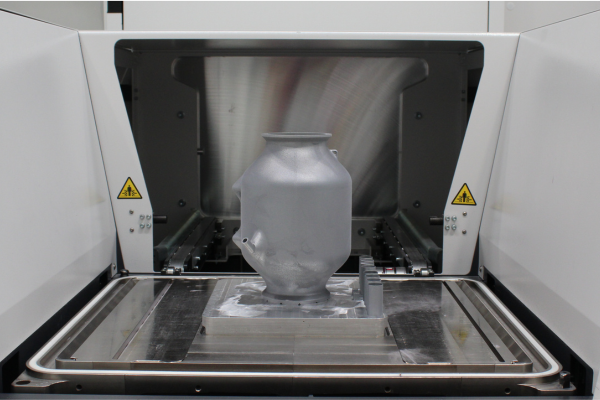

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

Case Study: Conflux Cartridge Heat Exchanger

Case Study: Conflux Cartridge Heat Exchanger

Case Study: Conflux Water Charge Air Cooler

Case Study: Conflux Water Charge Air Cooler