At Conflux Technology we use first principles to rapidly compare different concepts for their heat exchange, pressure drop, physical size and layout. This helps us save our design team hours of CAD design, simulation and analysis to just determine whether a design should be single or double pass, parallel-flow or counter-flow, wide and flat or narrow and long and many other key design decisions.

Conflux’s ever-expanding catalogue of fin designs, lattice structures and other heat exchanger geometries contains the information such as surface area density and pressure drop coefficients for certain fluids. These can be used to size fluid domains and helps lead into the next design stage where sub-cores are analysed and optimised.

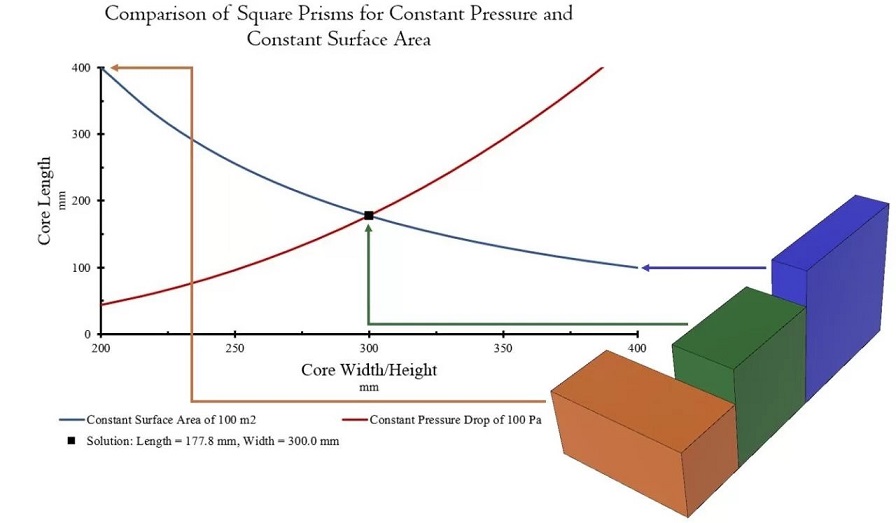

The image below shows the process of balancing pressure drop with surface area to determine the flow dimensions and flow length.