Conflux Quantify® is our proprietary quality control software. We developed it specifically due to our heat exchanger geometries and our manufacturing being so unique.

The key benefits of Conflux Quantify® are:

- improved quality control

- lighter/thinner/higher performance HXs due to improved development capabilities

- cheaper HXs due to the reduced need for trial-and-error development process (that is common in LPBF process development)

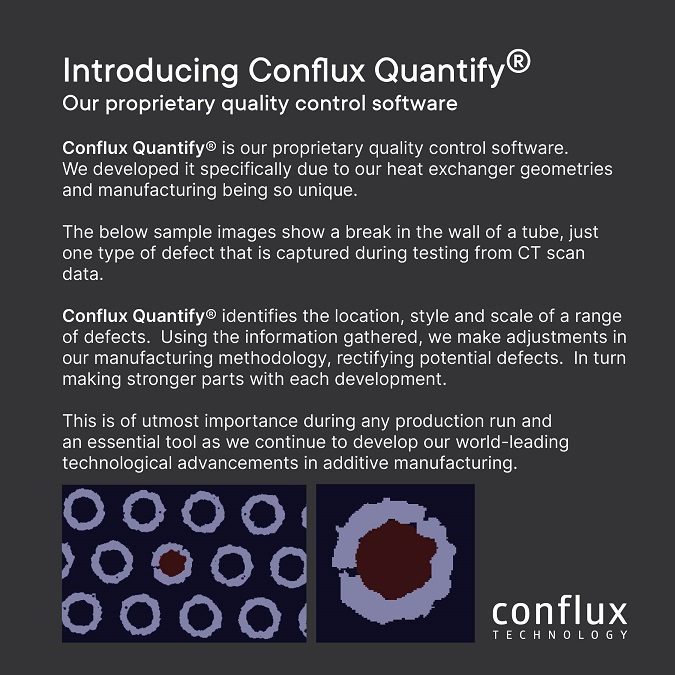

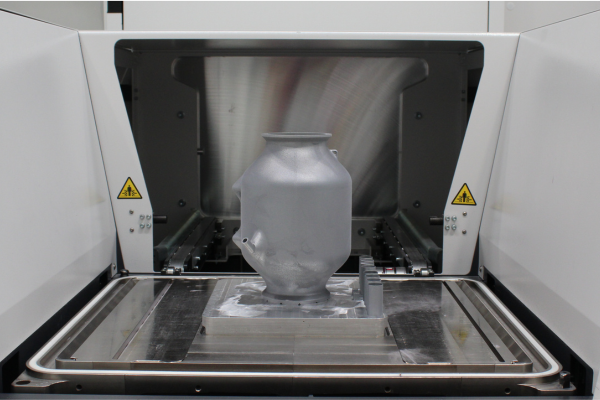

Our Conflux Quantify® software provides quantified analysis of large CT data sets by scanning entire heat exchanges or a series of parts. The data gathered from the CT scanning is a series of images that represent X-Y slices of the scanned part. These data sets are necessarily extremely large due to the required resolution, making manual analysis impossible. For example, to find a single ‘crack’ in the wall of a heat exchanger you’d have to look over five to ten thousand images for a crack that is just tens of pixels across. Or in the other extreme, if you’re looking for pores (I.e., small cavities within the part), there could potentially be hundreds in a single image across thousands of images. To manually count and measure such pores would be impossible for any significant data set.

Some of the areas that Conflux Quantify® looks at are surface roughness, wall thickness and pore morphology.

- -Surface roughness can play a large role in performance due to the relative size of the fluid domains. Thus, we are looking for small scale surface deviations.

- Wall thickness also plays a large role in performance. When observing wall thickness, we determine the mean of it, this is useful for very thin walls with high surface roughness.

- Pore Morphology and size distribution; we’re assessing the shape, size, and number of pores present. The metric we use for pore morphology is sphericity (I.e., how close the pores are to a sphere), and in combination with the size distribution, this can help inform the mechanism by which pore formation occurred. Laser Powder Bed Fusion (LPBF) process parameters will impact pore formation, and hence this tool can be used to inform parameter development as well as quality control.

Defect detection is also especially important in all areas; a single crack would render a part unusable. Given the monolithic structure of Conflux’s additively manufactured heat exchangers, without Conflux Quantify® observing possible internal defects is often not possible without a destructive inspection process.

In addition to this, Conflux Technology uses proprietary LPBF parameter sets that allow us to print geometries otherwise not possible. Hence unlike OEM qualified parameter sets, defect formation is not known and must be determined by our own development and inspection processes.

In short, Conflux Quantify® will give us repeatable, comparable measurements and helps inform us for process development decisions, parameter development, and performance predictions.

#additivemanufacturing #3dprinting #innovation