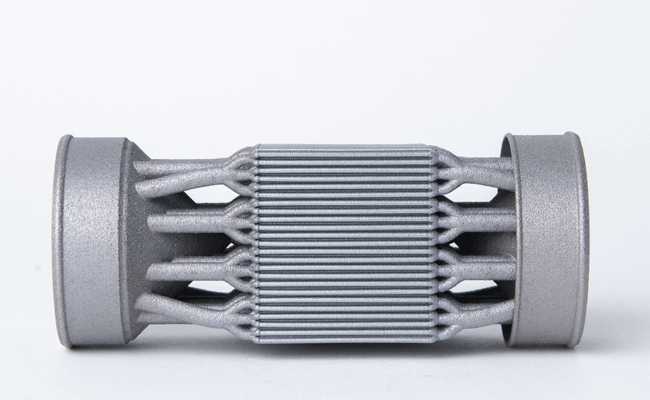

Additive Manufacturing (AM) enables shapes and forms that are not possible with traditional manufacturing.

Traditional manufacturing relies on subtractive processes (creating parts by removing or cutting away from a solid block of material) and/or joining many simple components together. AM is an additive process, where parts are built incrementally, one layer at a time, and often as a single piece rather than many.

There are profound implications of this development and the resulting complex geometries that can now be made, but contrary to popular belief it is not possible to print anything and everything. Conflux prides itself on pushing the limits of what AM can do. Our focus is inch wide, mile deep: AM heat exchangers.

As with any new technology, AM demands specialists with a suite of skillsets who that go beyond previous practices and focus on this new territory and its intricacies. Our team creates detailed geometries that cannot be manufactured using any other method, nor by any other AM team.

Heat exchangers produced via additive manufacturing offer potential benefits for wide ranging industries and applications:

Conflux Technology is known industry wide as the pioneers of additive manufactured heat exchange technology. Our specialist knowledge of thermo fluid dynamics engineering is combined with more than 20 years experience and success in metal additive manufacturing– from design and CFD analysis through to in-house AM production, post-processing and independent validation.

We’ve developed a vertically integrated business with experts at each step of the way incorporating powerful and unique capabilities like our use of the Australian Synchotron, our inhouse quality control software Conflux Quantify or our vast library of proprietary parameters. Partner with us and harness the benefits of our experience for your own gain.