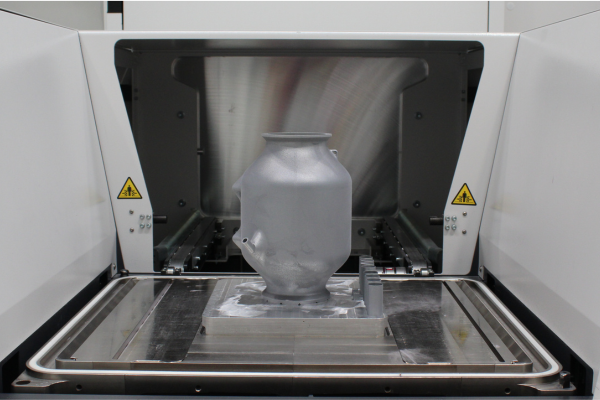

One of the main features in our new EOS M300-4 we are excited about is the 4x lasers within the chamber, massively reducing our build time.

Our new M300-4 will arrive in our warehouse shortly. We are enthusiastic about a lot of the features that it will come with; a larger chamber, double recoating, new U.I., improved gas flow, advancement in software, etc.

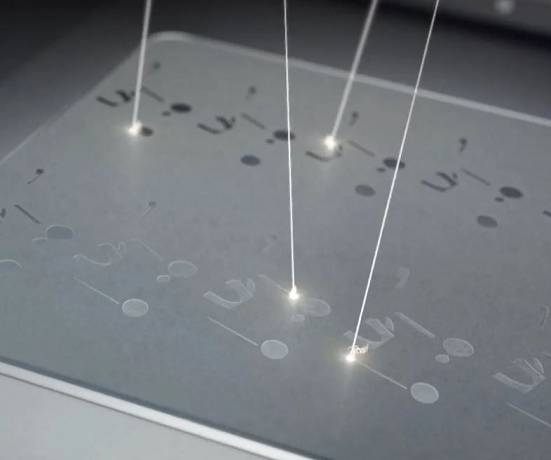

As for the lasers, these are Yb-fiber laser 4 X 400W, simply translated are high peak power lasers that emit clean, ultrafast pulses. Perfect for the Laser Powder Bed Fusion (LPBF) process.

Not long ago, only one Yb-fiber laser would do the work across the whole build. Shortly after, with a new generation of machines, four of these types of lasers (Yb-fiber) are now working in unison within the same chamber. However, each of these lasers would work only within their allocated quadrant. So, if a section of the build item was particularly complex the other three lasers would have to wait while the single laser was complete on its segment before they could all move on to the next section.

Now, with our new M300-4, all four lasers can work anywhere in the chamber at the same time. Meaning, that if there is a complex part of the build all four lasers can focus on that area simultaneously, considerably reducing the build time when compared to either of the types mentioned.