C H A L L E N G E - To create a higher performing, lighter weight heat exchanger for Formula OneThis is the story about the foundation on which Conflux Technology was built – our first patented design …

C H A L L E N G E - To create a higher performing, lighter weight heat exchanger for Formula OneThis is the story about the foundation on which Conflux Technology was built – our first patented design …

Conflux Technology – an Australian metal additive manufacturing (AM) innovator of heat exchangers, led by Michael Fuller – are pleased to announce their commencement towards the Aerospace certificatio …

Conflux is proud to announce we have concluded a successful project with Atlas Copco to investigate the next generation of heat exchangers for their compressor systems. Atlas Copco had wanted to inves …

While strides have been made over a relatively short period of time in additive manufactured heat exchange technology, there are still a number of obstacles that must be overcome to scale up to mass m …

We happy to announce we are working with General Atomics Aeronautical on a Fuel Oil Heat Exchanger for the MQ-9B. “GA-ASI (General Atomics Aeronautical Systems Inc) wants to optimize and augment the …

It is predicted that by 2025 we will interact with a data centre every 18 seconds [1] as our appetite and reliance on the internet continues to grow. This has led to a boom in the electronics industry …

Conflux Technology will now be represented by Jive Solutions in Korea, as part of a Representative Agreement. This partnership brings together Jive Solutions, a total solution provider for 3D printing …

News

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Conflux Technology enters production on metal 3D printed argon heat exchanger for upgraded AMCM M 4K

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Jive Solutions to represent Conflux Technology thermal solutions in South Korea

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Conflux Technology achieves Aerospace Certification AS9100D for Design and Production

Media

FAQ

Case Studies

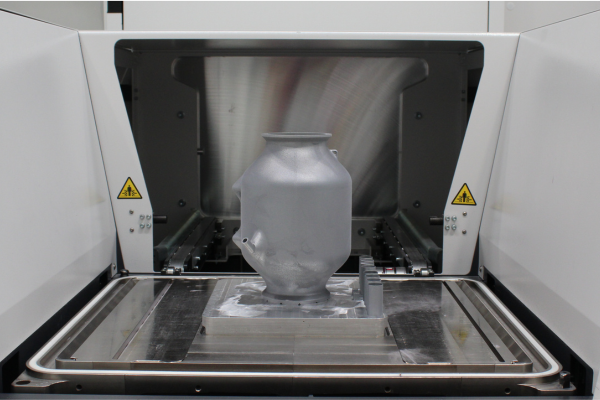

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

Argon Gas Heat Exchanger for AMCM's metal 3D printing machines

Case Study: Conflux Cartridge Heat Exchanger

Case Study: Conflux Cartridge Heat Exchanger

Case Study: Conflux Water Charge Air Cooler

Case Study: Conflux Water Charge Air Cooler